QUALİTY

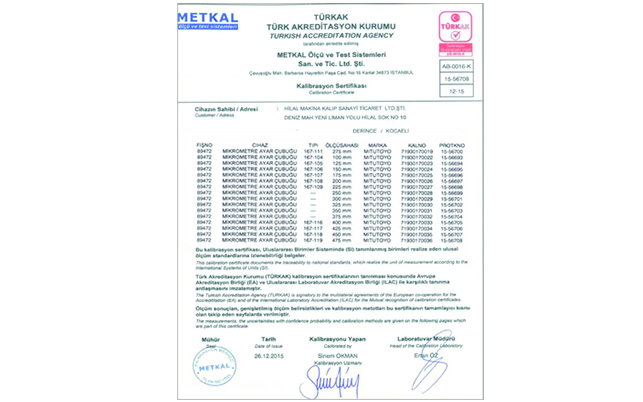

In HİLAL MAKİNA ve KALIP SANAYİ LTD.ŞTİ, the high quality of products is ensured with Quality Control methods applied rigorously in all steps such as before production, during production and after production stages. The innovative quality control methods of high sensibility warranty the conformity with the customer requisites. Therefore, we use high precision conventional measuring devices.

In HİLAL MAKİNA ve KALIP SANAYİ LTD.ŞTİ, the high quality of products is ensured with Quality Control methods applied rigorously in all steps such as before production, during production and after production stages. The innovative quality control methods of high sensibility warranty the conformity with the customer requisites. Therefore, we use high precision conventional measuring devices.

The process used in our company concerning the raw materials is constituted of the control of size ad surface before rough machining, ultrasonic control, control of size and surface after rough machining, surface sensitivity measurement, hardness control, final product control and control of packing and packaging.

CALLIPER |

|

HOLE METER (It can measure between O-1500 MM) Hilal Makina| Machine manufacturing Spare Parts Manufacturing |

|

MICROMETER (It can measure between 0-1500 MM.) Hilal Makina| Machine manufacturing Spare Parts Manufacturing |

|

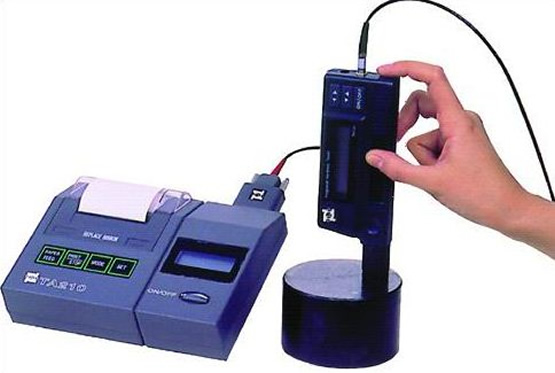

HARDNESS METER (The hardness meter of TH130 Model allows control the hardness of the parts when necessary.) Hilal Makina| Machine manufacturing Spare Parts Manufacturing |

|

SURFACE ROUGHNESS MEASURING DEVICE (The surface roughness measuring device of SJ-231 Mitutoyo model and brand name allows control the surface quality of the parts when necessary.) Rolex Replica |

|